Menu

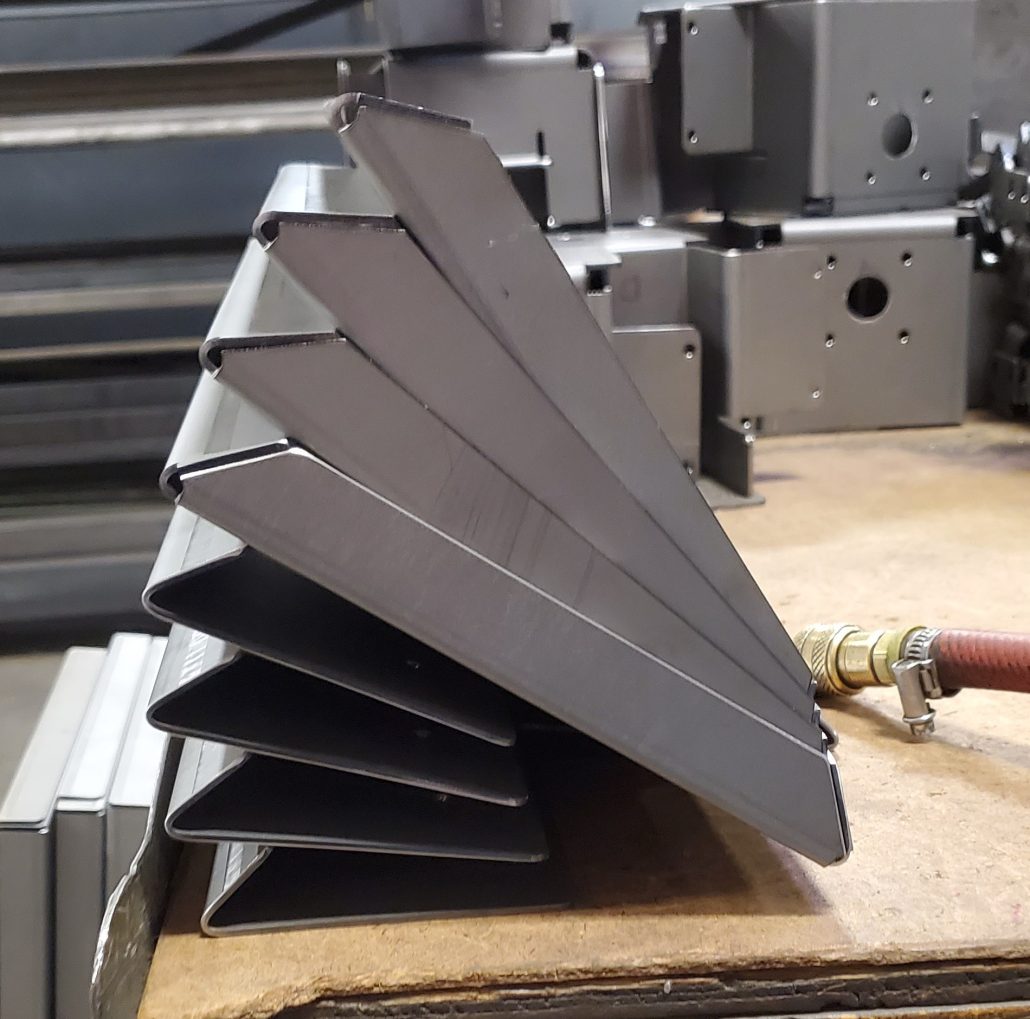

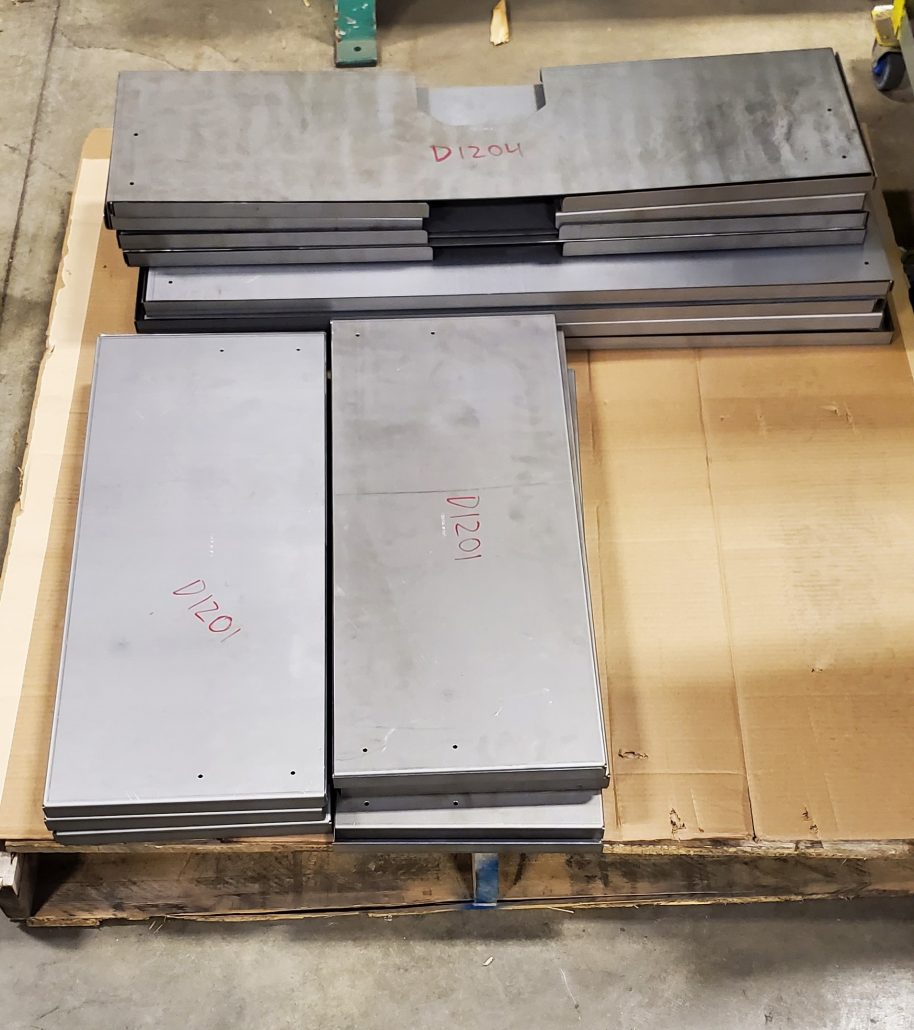

Eagle Masking utilizes a computer aided 80 ton break as well as a 120 ton manual press to preform a wide variety of bends to support our daily tooling manufacturing. Allow us to offer our knowledge and experience in your next project. From simple bent brackets to multi-bend profiles we have the ability and tools to make it a reality. We are capable of supporting volumes as low as one piece up to small production runs.

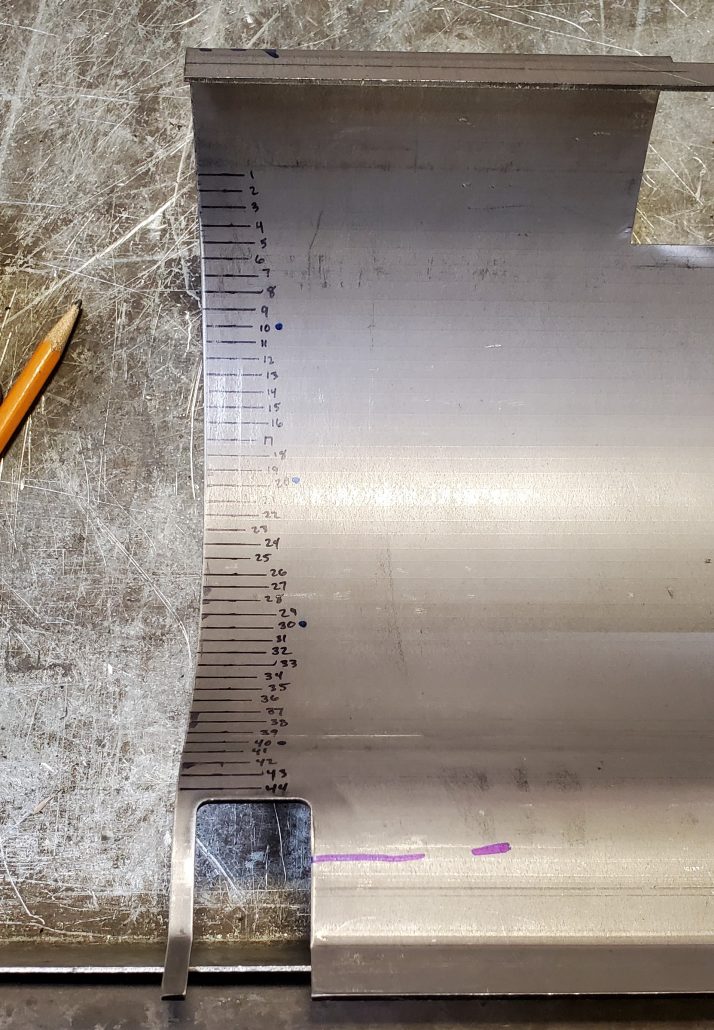

Our Amada HG 8025 is state of the art and is our primary tool for all of our break operations. It features a computerized controller and software that allow for multi-step bends and consistent set up. This machines ensures the upmost accuracy and precision in every bend. Each part is programed and retained to be called up next time a given piece is required. If additional parts are needed months or years down the line we are able to replicate the part and maintain the consistency in your product line. This machine is capable of bending steel, aluminum, stainless steel, as well as some plastics.

The amada break is capable of programing multiple bends per piece and cycling through each bend until the part is complete. This is ideal for small to larger production runs where a program can be established to perform a series of bends and then resetting for the next piece. Leads to quicker processing time and the ability to handle production level runs in an efficient and timely manor

For those projects that require much longer bends or thicker materials we have a manual 220 ton Jenesis press. This provides that extra bending force to achieve these bends. Allow us to use our years of experience to make even your largest projects a breeze.